Europes Largest & UK Exclusive Specialist. Hand made boutique guitars from Europe that will change your entire understanding and experience whenbuying a new acoustic guitar

The Dowina Guitar Centre

Richard Introduced Furch Guitars To The UK 20 years ago and the reason we dont sell mass-produced "hi profile" brands. Furch are the benchmark tp which other brands aspire to.

THE Furch Guitar Centre

With an incredible Back story - A Truly Brtiish yet global brand utilising the shared skills of the Gordon Smith Team in England and a small boutique workshop in China - The result? Unbelievable quality that far surpasses that of recognised mass produced brands at the same price.

AUDEN GUITARS UK CENTRAL

The Uks Largest & Longest Serving dealer. Thousands of customer reviews online - we are here to help online and at our showroom

Eastman Guitars

Guitars You'd be crazy to Ignore...

For me - there is no difference between "personal" and "business" life - It is all "my life". Interconnected and therefore highly personal. Every guitar I sell (EVERY) is one I can tell you the backstory - about the people who make them - the ethos of the brand and how they align with my own - they are a genuine personal recommendations based on 28 years in the industry.

With the industry dominated by marketing, hype, and "blinkered" brand loyalty - retailers focus on what they get asked for - with little effort in raising awareness of guitars that are better than the one you asked about. This leads to a lot of poor buying decisions!

Here is a quick introduction to the brands I often refer to as "my babies" but really you could simply refer to them as "benchmarks". Check the prices - check the specs - check the quality and back story - and find me a brand that does it better - or even close. The fact is you cant buy a bad guitar from Richards Guitars - you will only find the best - set up to your personal requirements.

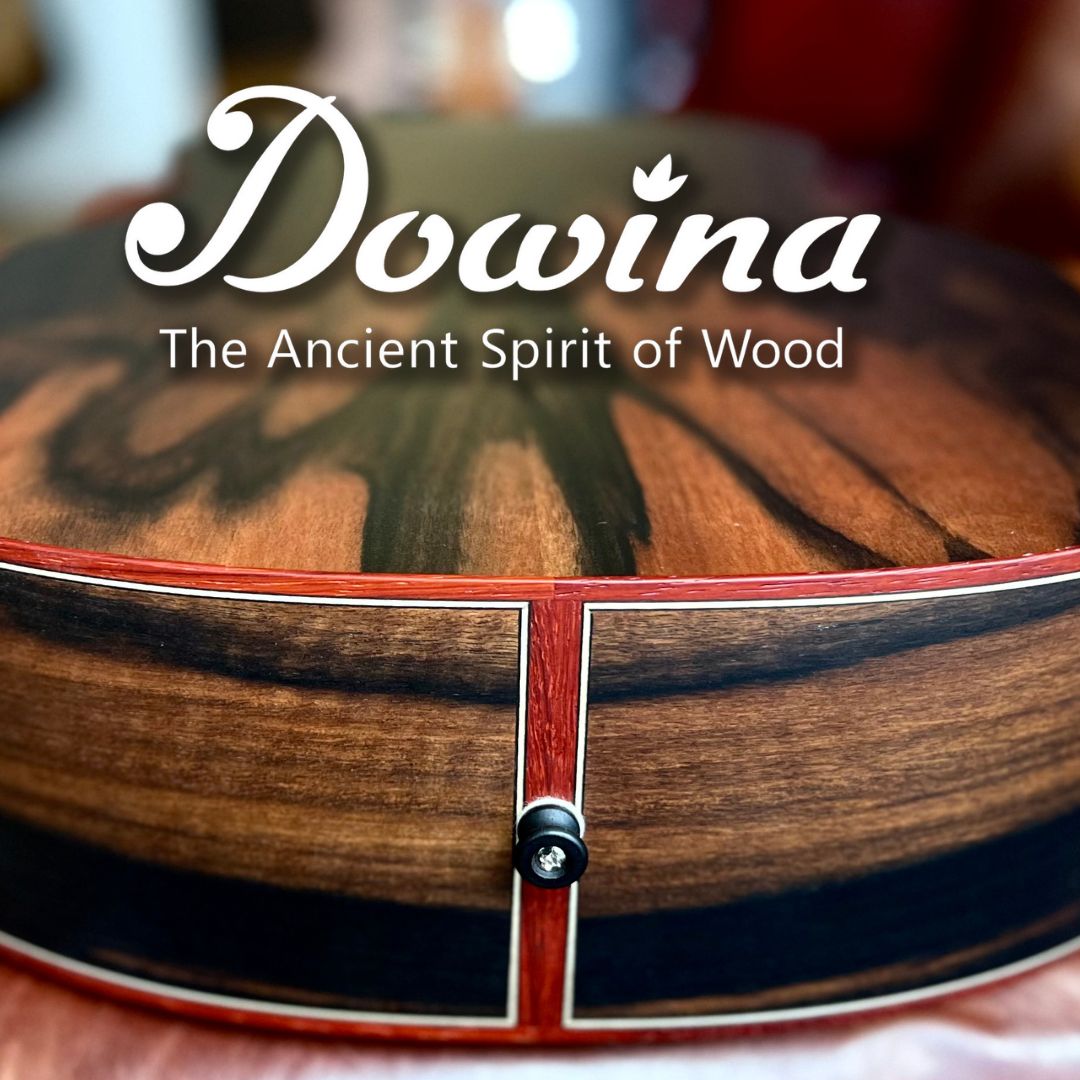

Art Meets Craft - Artisan - Unique

Hand Made In Slovakia

I have the honour and privilege to be Englands exclusive dealer for Dowina guitars. A completely unique approach to guitar building that blends passion, art and craft producing the most inspiring and wondrous acoustic guitars that represent so much more than the materials they are made from.

Dowina is more than just a guitar - its an experience that you will appreciate and remember for a lifetime.

Buy Dowina Guitars Online

Detail - Clarity-Power-Resonance-Beauty

Furch Changed Everything...

I introduced Furch to to the UK over 20 years ago - with my good friend Keith Twine who has since retired.

At the time I was a leading supplier of brands such as Gibson, Martin & Taylor. Experiencing Furch guitars made me realize there is what you "know" and what you "should know". Just because you DON'T - doesn't mean it doesn't exist!

What does all this mean? Forget what you think you know and open your mind to the possibility that you can find better - and we will guarantee you an experience you will never forget - with help from Furch and my other personal finds from over the decades.

Buy Furch Guitars Online

Inspirational quality, tone & feel at a price you never thought would be possible.

A Benchmark British Brand

With an incredible Back story - A Truly Brtiish yet global brand utilising the shared skills of the Gordon Smith Team in England and a small boutique workshop in China - The result? Unbelievable quality that far surpasses that of recognised mass produced brands at the same price.

Buy Auden Guitars Online

Hand Made - Standard Setting - Affordable

We Were The First UK Dealer for Eastman Guitars...

....and continue to be their largest and most experienced dealer in the UK supplying Eastman guitars throughout Europe.

Originally known for their extraordinary quality, hand made arch tops - produced by violin makers - as their reputation spread they developed into the World of electric and acoustic guitar production which continue to be made by hand.

Eastman have now become a hugely dominant force in the Guitar World producing the "best in class" in any guitar genre they opt to focus on.

Nobody knows them better or can provide you a better experience.

Whether you decide on the showroom experience or buying online you could not be in safer hands.

Buy Eastman Guitars Online

The Truly Great British Electric Guitar Brand Since 1974

The Great British Electric Guitar Brand was born just 2 years after me!

I first became entwined with Gordon Smith in 1995 when I began selling guitars. My first experience was on receiving what I later learned to be a Gordon Smith Gypsy.

So powerful an impact that guitar had on me that I kept it and gave it to my Dad. Its the ONLY guitar in 28 years I havent parted with (well - My Dad has it and continues to enjoy it at 82).

The Gordon Smith Legacy rocketed to new heights when Doug Sparkes took over about 10 years ago - taking this great British Electric Guitar brand into new realms not just in terms of value but extreme quality too - making them not just a choice for people who want to support British Guitar Building but for people who want the finest electric guitars too.

Buy Gordon Smith Guitars Online

Quality - Versatility - Innovation

Canadas Finest

I have specialised in Godin guitars since 1995.

Godin have been solving problems for performing acoustic and electric guitar players for over 30 years, producing the most divine instruments which are stylish, of the highest quality whilst serving the practical needs of the modern performing professional

You could say Godin is the antithesis to Gibson! Godins reputation is built largely on the word of mouth of professionals and session musicians who need their instruments to be highly reliable and consistent night after night.

Get one in your hands, and you will soon understand their unique contribution to the evolution of the guitar.

Buy Godin Guitars Online

Perfection

Hand Made In Italy

I have to thank Stuart - Director of UK Distributor Selectron for thinking of me when he made a very special find in the guise of Luigi - A man building what can only be described as playable works of art. An extraordinary man - extraordinary guitars and I can only thank Luigi & Stuart for thinking of me as a perfect fit to help represent Luigis work in the UK.

Buy Valenti Guitars Online

The most comprehensive collection of affordable electric guitars money can buy.

We will help you find The best playing - Affordable electric guitar

I have been promoting Vintage brand guitars since the day they were "born" some 20+ years ago! In this time they have just got better... and better... and better! Not just that but the range has just become EPIC. Something for everyone!!

In the past couple of years ProShop has become one of the mmost exciting UK hand built guitars- using the Vintage range as the building blocks to create wonderful and exciting guitars that would normally cost thousands of pounds.

Buy Vintage Brand Guitars Online